Category : MACHINES

By Formbytes Technologies(Spain)

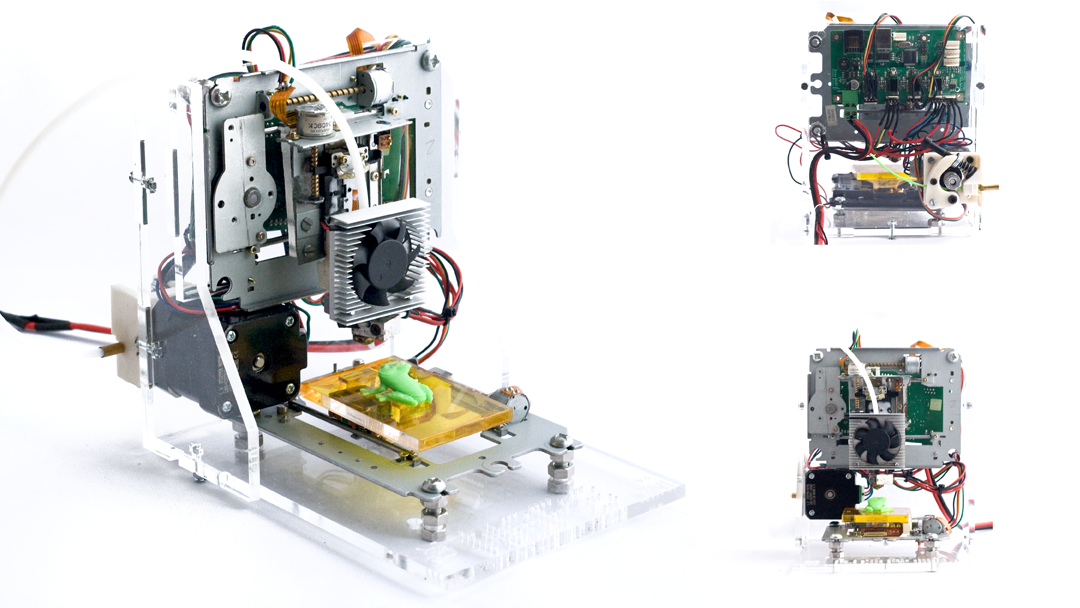

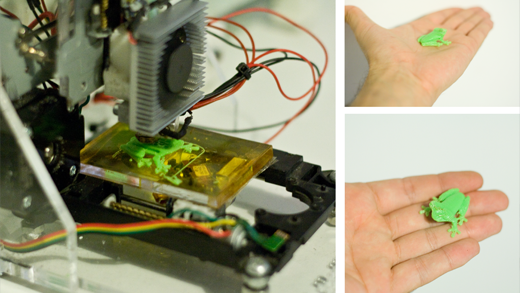

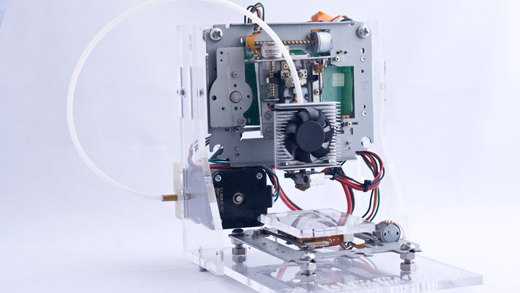

This project describes the design of a very low budget 3D Printer that is mainly built out of recycled electronic components. The result is a small format printer for less than 100$.

On one side you get an introduction to machine building and digital fabrication and on the other side you get a small 3D Printer built out of reused electronic parts. This should help us to be more conscious about the big problems related with e-waste generation.

Our intention with this project was to bring the digital manufacturing and 3d printing with its huge potential to everibody. We thought the best way to do it would be through breaking the price barrier and what better way to do that with e-waste as a major problem globally.

The result was to make a step by step manual and publish it with CC license on the network and amazing mind, what has happened to us is that shortly after we had 500 K visits (nearly 1000 Kcurrently) and the Inbox full of messages from countries as diverse as the India thanking us the document and open a project like this as well as many images of this same machine being replicated by many sites and many schools especially.

http://www.instructables.com/id/eWaste-60-3DPrinter/?&sort=ACTIVE&limit=40&offset=40#DISCUSS

[About the Fab Machine]

The 3D Printer is built with about an 80% of recycled components, which gives it a great potential and helps to reduce the cost significantly.

Hiroya Tanaka

Hiroya Tanaka

Although it is reminiscent of W.Afate 3D printer by FabLab Togo that received the top prize at Fab Awards at Fab10 in Barcelona, this creative work has a very deep social meaning.

Luke Yeung

Luke Yeung

Achieving a closed-loop cycle remains a beautiful but distant dream for most tools and fabrication. This is why idea of the EWaste $60 3D Printer is so compelling - it's about designing a tool made from waste products to enable the printing and creation of new products. In addition to the recycling idea behind the design, there is the creative resourcefulness that comes from using locally available and even scavenged electronic materials. But the most significant thing for this product may simply be the economic benefits - if this printer can be developed to be as sophisticated as existing printers on the market, it can revolutionize the industry by dramatically reducing the cost of 3D printing. And that can have a huge impact in the way we can create and materialize our ideas and innovations for the future.