FINALIST

FINALIST

Digital Ice Core

Category : GENERAL

By Cy Keener, Sam Holmberg, Dave Eldenburg, Justine Holzman (USA)

Digital Ice Core from Cy Keener on Vimeo.

Cy Keener, Sam Holmberg, Dave Eldenburg, Justine Holzman

Cy Keener is an interdisciplinary artist who uses environmental sensing and kinetic sculpture to record and represent the natural world. He is an Assistant Professor of Sculpture and Emerging Technology at the University of Maryland’s Department of Art. His work includes a range of data-based installations to visualize diverse phenomena including sea ice, wind, rain and ocean waves. He received a Master of Fine Arts from Stanford University, and a Master of Architecture from the University of California, Berkeley.

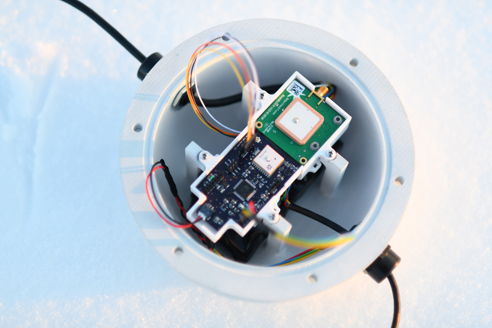

Digital Ice Core is a new media art project that brings gallery viewers in contact with Arctic sea ice. Using electronics, data and satellite communication, it links electronics deployed by the artist at a remote field site with a digital light sculpture, enabling viewers to see the ambient light in the air, ice and ocean below in close to real time. On April 5 2019, a custom sensor installation was placed by Cy Keener on a piece of multi-year sea ice near Utqiagvik, Alaska. A five cm diameter, 2 m deep hole was drilled through the ice, and a set of 3.2m light and temperature sensors were threaded through the ice, into the ocean below. These sensors were supported by a custom designed enclosure holding electronics, a battery and a satellite modem. Each day at 12:30pm local time, light and temperature readings are collected over the length of the sensors. These readings are transmitted via satellite, and the light sculpture shows ice thickness in pulsing light, using the corresponding RGB values from the sensors. The ocean below is indicated with a flickering blue light.

This project is intended to connect the general public to Arctic sea ice, and demonstrate that an open source art-based STEAM approach to design and fabrication can contribute to science. Digital Ice Core enables viewers to experience multiyear sea ice in the Arctic, before this kind of ice disappears completely due to climate change. “Very old (multiyear) Arctic ice has declined by 95% in the last 33 years.”* This artwork lets viewers witness current ice conditions and watch the ice thickness change over time. It also creates a digital / visual record of the ice to share with future generations. In addition to art-based data visualization, the project demonstrates that scientific instruments can be fabricated using a low cost, open source approach including ‘Maker’ software and desktop fabrication tools. Atmospheric pressure and external temperature readings from each buoy are currently contributing to the International Arctic Buoy Programme dataset.*

* This data is used for scientific purposes and relied on by numerical weather prediction models to develop forecasts for the Northern Hemisphere.

*https://arctic.noaa.gov/Report-Card/Report-Card-2018/ArtMID/7878/ArticleID/772/Executive-Summary

*http://iabp.apl.washington.edu/maps_daily_map.html

One of the goals of this project was to see if it was possible to design and build a science grade buoy that could survive extreme Arctic conditions using a ‘maker’ approach to fabrication and open source or free software. The buoy was modeled using a mix of Grasshopper, Fusion 360, and Eagle. The heart of the project is a custom circuit board designed in Eagle from a mash-up of open source design files from Adafruit and Arduino. The Eagle file was then imported into Fusion 360, and the enclosure was designed around it as well as a cold weather battery, satellite modem and sensors. Multiple options for the exterior surface were coded in Grasshopper, with the aesthetic goal of having a simple form disrupted or disturbed by wave-like patterns. These Fusion and Grasshopper models were brought together through Meshmixer, and the result was 3D printed on a nylon 3D printer at the Autodesk Technology Center in Toronto. The Digital Ice Core data visualization light sculpture was modeled in Fusion 360, and fabricated using stock parts, water jet cut parts, and hand techniques. The light comes from over 1,200 RGB LEDs run by Arduino code.