GENERAL AWARD

GENERAL AWARD

3D Weaver

Category : GENERAL

By Oluwaseyi Sosanya /Sosa Fresh (United Kingdom)

3D WEAVER from Zuzanna Weiss on Vimeo.

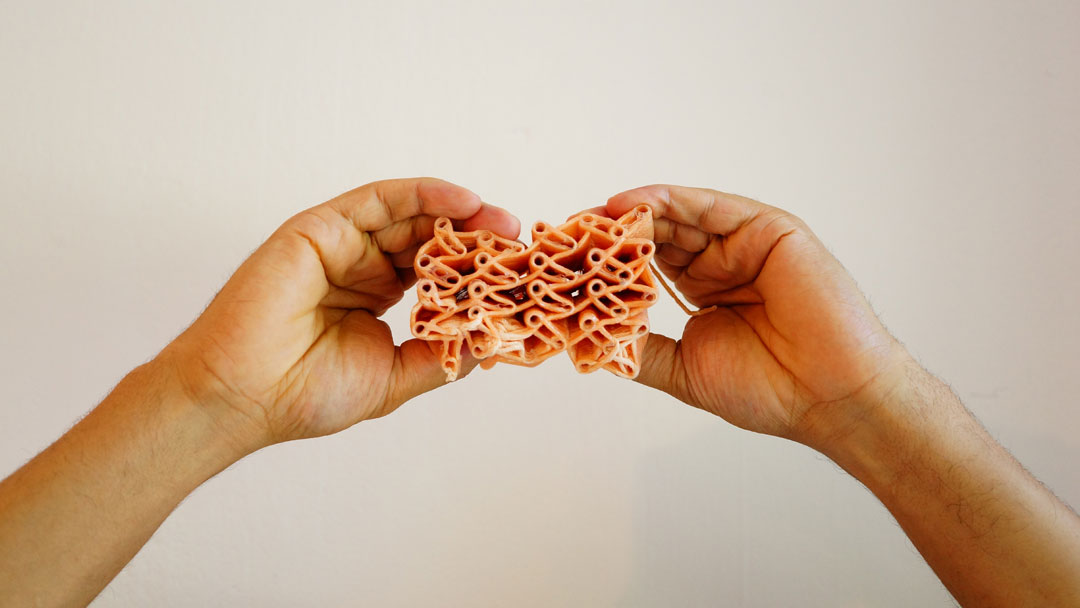

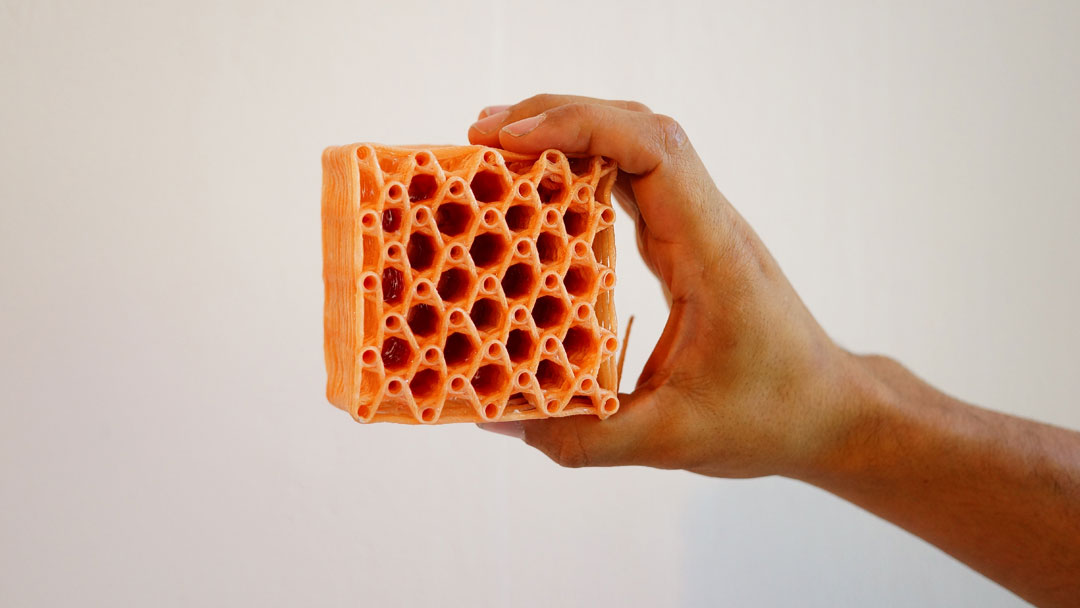

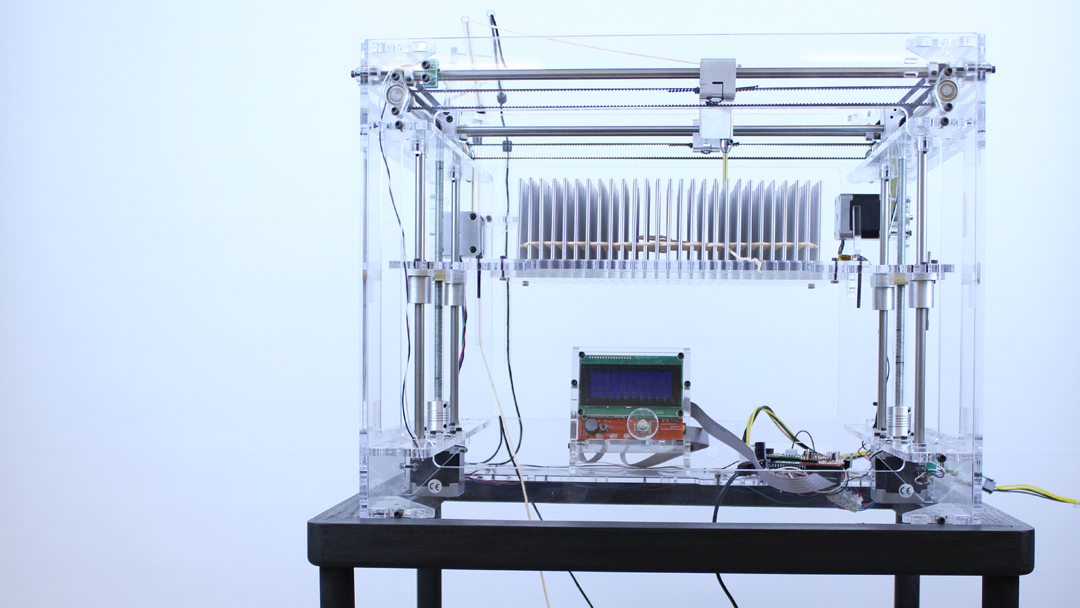

The 3D Weaver is a loom designed specifically to weave three-dimensional structures using the x y and z coordinates. The machine runs on g-code, the most widely used numerical control programming language, often used in industrial CNC milling. The warp of a normal woven process is replaced with tubes (warp tube) and the weft is fed through a nozzle and pulled in tension around each tube as the g-code is being executed.

The 3D Weaver is creating a new type of textile: one which could have pre-programed mechanical properties tailored to a specific use. In this regard, there are countless types of products you can produce with the 3D Weaver. I intended to look at textiles on the human wearable scale. Therefore, the products I have been producing are around the wearable area. High-end sportswear and footwear have been my early applications.

Every woven structure is based on a binary pattern composed of 0s and 1s. These patterns determine the order in which the threads of a weave are interlaced. By rearranging these patterns, a variety of structures can be created. Looms were developed to manage the order of these patterns, thus allowing us to weave textiles in large quantities. Looms work in two dimensions, therefore to create three-dimensional structures on a standard loom, a very specific pattern must be developed, and there is still a limitation of the machine. We are in an exciting time of textile innovation with new materials, surface treatments and applications being developed each day. There is a clear space for innovation in production process that will make open new applications. The target applications for the proposed structures center on the implementation of these fabrics in garments, footwear, and accessories that are considered casual everyday wear. There is a clear market demand for new and innovative textiles, which can be incorporated into casual daily wear. Investigating the line between military, sports wear and casual wear opens possible avenues for innovation.

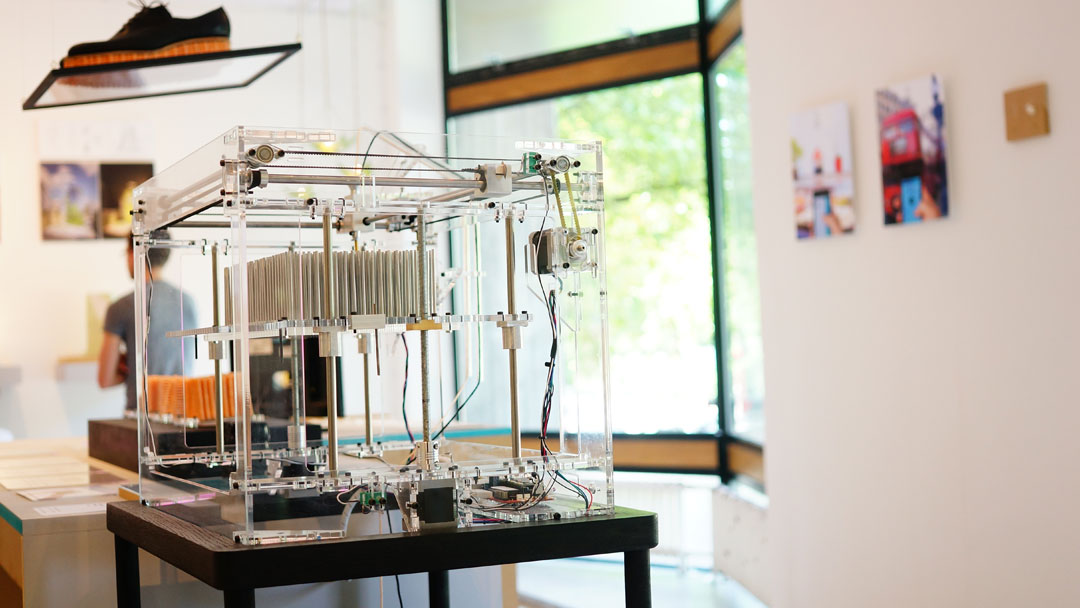

With a background in mechanical engineering and the resources of Royal College of Art at a finger length I quickly began developing test rigs and jigs to create samples of the structures I was looking to achieve. Things began to get complicated and it became clear that I would need to develop a method for creating the structures which would allow me to explore new ideas and directions.

The 3D Weaver was designed and built to allow freedom in three axis. With the tool I was able to explore a variety of woven structures and achieve structures I had been looking for.

With this project I wanted to program behavior and mechanics into the structions. The ultimate goal is for this process to be used in sportswear and wearable garments that can offer flexibility and movement and protection all with one material and a variety of structures this is offering a new type of sensation with our clothing and a new conversation around what protective garments look and feel like. In addition to protective medical apparel, textiles in fiber and fabric form are used as implants, filters and surgical dressings. Recent decades have witnessed major development in medical textile production, offering a new type of haptic application.

Laser cutter, CNC milling machine, 3D Modeling and Design Software

JUDGES, COMMENTS

-

Hiroya Tanaka

Professor at Keio University, Representative of SFC Social Fabrication LabMoving forward, in order to create new designs, we need to create using new equipment and new tools. I selected this works as it is symbolic of this very concept.

-

Cleo Huet

Product designer

Professor at Haute Ecole des Arts du Rhin (HEAR)The material as much as the machine opens new territory of investigation. It is always exciting to imagine a new field of research!

-

Shiho Fukuhara

Artist

Co-Founder, BCL / CEO, Poiesis LabsI think knitting technology will go along great with the digital fabrication. I think it is interesting how the creator designed the equipment and the filament. I also think that it being called “Weaving” is also interesting.