FINALIST

FINALIST

Transformative Appetite

Category : STUDENT

By Tangible Media Group, MIT Media Lab (United States)

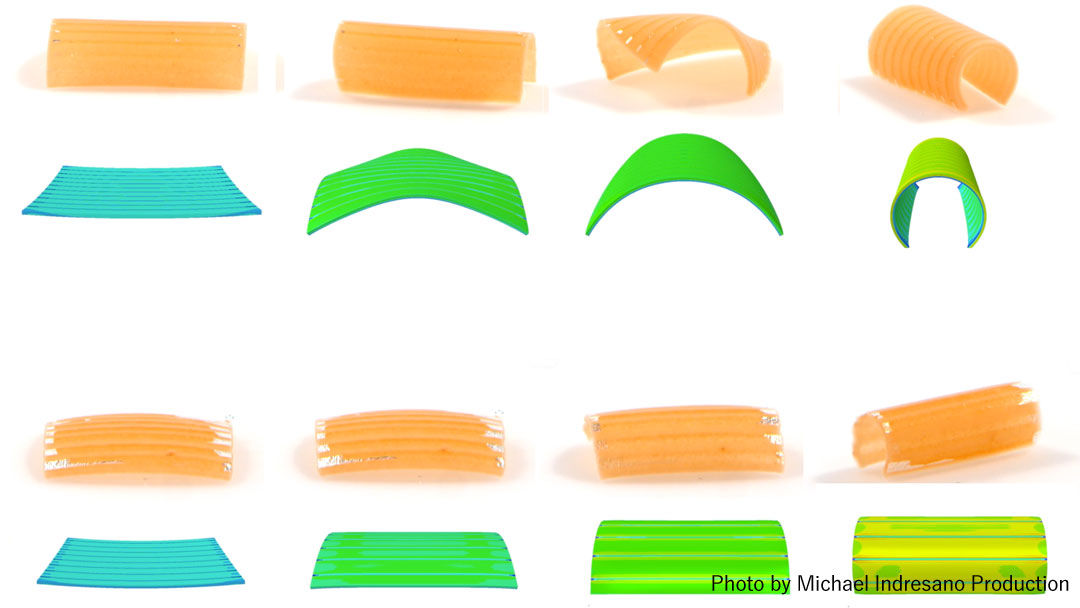

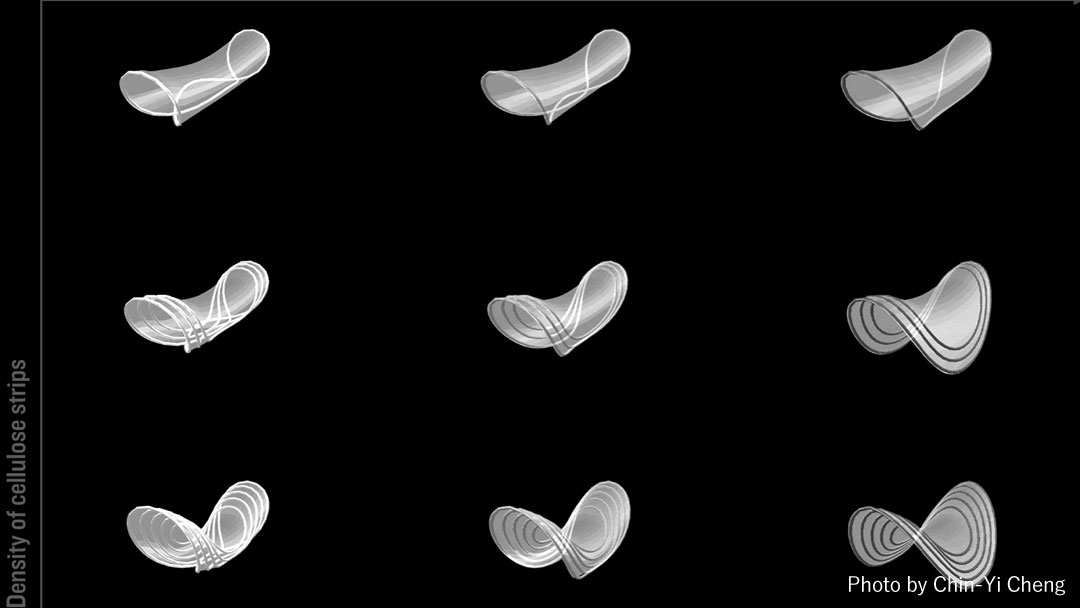

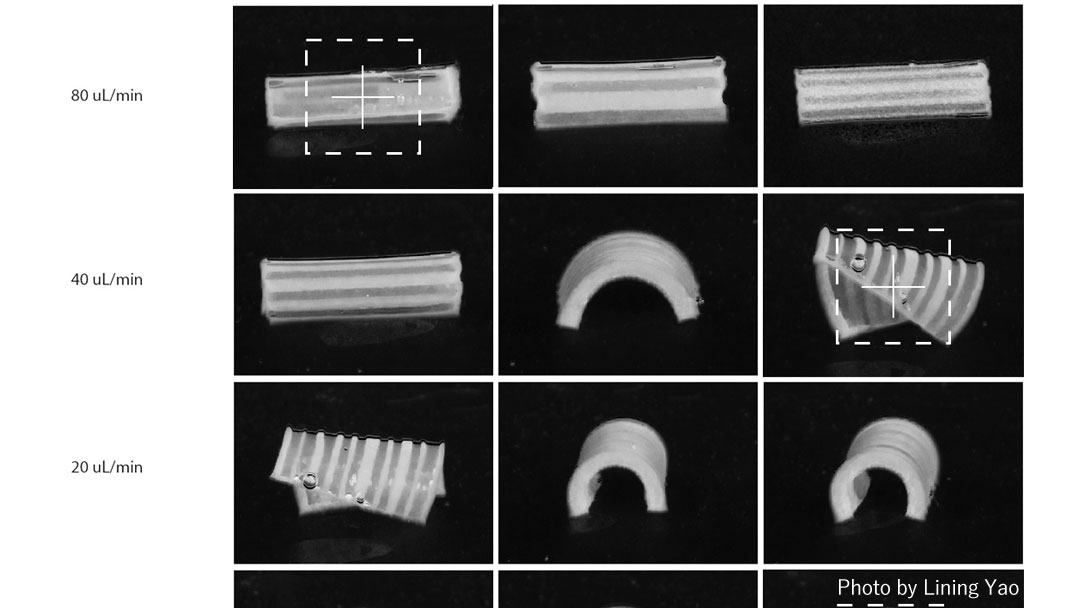

We developed a concept of transformative appetite, where edible 2D films made of common food materials (protein, fiber or starch) can transform into 3D food during cooking. This transformation process is triggered by water, and it is strongly compatible with the ‘flat packaging’ concept for substantially reducing shipping costs and storage space. Users can customize food shape transformations through a pre-defined simulation platform, and then fabricate these designed patterns using additive manufacturing. By working closely with a chef, we created many magnificent shape-changing food, which could enrich the dining experience and address the needs of the aging population.

Project TA: http://tangible.media.mit.edu/project/transformative-appetite/

TMG: http://tangible.media.mit.edu

Media Lab: https://www.media.mit.edu

In modern society, food produced locally has become scarce. Much of the food in urban regions is produced remotely and shipped to customer, resulting in pollution to the air due to the emissions of greenhouse gases to the environment.

This work was inspired by the movie – Star Wars: The Force Awakens, where the actress Rey makes her bread by putting edible powders into water. The flat-packed food proposed in this work, may partially alleviate pollution, by reducing the amount of air shipped during food transport. For instance, in the package of traditional macaroni pasta, more than 67.3% of volume in the package is air. If instead we are able to flat-pack pasta, and transform it into 3D shapes during cooking, more than half of the space during shipping and storage will be saved.

To develop these transformable foods, we performed material-based design, established a hybrid fabrication strategy, and conducted performance simulation. We made a bi-layered edible film by advanced material processing, and used a customized 3D printer to make the shape-changing pattern. We characterized the food texture by texture analyzer and scanning electron microscope. We predicted the performance of the edible film by finite element (FE) simulations with software ABAQUS. To facilitate design and predict the shape transformation of these edible films, we built a digital material design and simulation interface with JavaScript, Rhinoceros, and Grasshopper.

Three application techniques are provided: 2D-to-3D folding, hydration-induced wrapping, and temperature-induced self-fragmentation, to present the shape, texture, and interaction with food materials. Based on this concept, several dishes were created in the kitchen, to demonstrate the futuristic dining experience through materials-based interaction design.

3D printer, Cutting machine, 3D Modeling and Design Software, 2D Design and 2D CAD Software

MEMBER

- Designer

- Dr. Wen Wang

- Designer

- Dr. Lining Yao

- Designer

- Mr. Chin-Yi Cheng

- Designer

- Dr. Teng Zhang

- Designer

- Mr. Daniel Levine

- Designer

- Prof. Hiroshi Ishii

- Producer

- Dr. Lining Yao

- Producer

- Michael Indresano Production

- Sound Composer

- Fragmento Universo

JUDGES, COMMENTS

-

Shiho Fukuhara

Artist

Co-Founder, BCL / CEO, Poiesis Labs3D printing is not usually a method for mass production. That being said, this work may widen the possibilities of 3D printing as a whole. It is incredibly interesting how in a sense this is 4D printing, because it also includes time as a dimension of creation. The engineering aspect is also wonderful. As for the presentation, the video was unexpectedly beautiful. Some doubt remains as to whether it would be possible to scale this project for mass production. I look forward to this work’s evolution, particularly, in terms of how it relates to many of society’s problems such as food consumption in the cities, food logistics, and caring for the elderly.